Polyethylene Film Extrusion Explained

Three-layer film blowing machine is process that creates thin plastic films. Films like these are extensively used in packaging items as manufactured by companies such Tri-Cast. It is a rather novel medium and has been increasing in adoption circle of the manufacturing world. These are extremely light and robust polyethylene films which make them perfect for numerous uses. They also recyclable, awesome for the environment. This Xinfu uv resistant polyethylene film also does not tear easily, and are resistant to the detrimental effects of sunlight and standing water

Every day, new technology comes out for XINFU polythene film extruders as an increasing number of people are looking for environmentally conscious packaging solutions. With new raw materials at use, some companies are now utilizing plant-made or biodegradable products for instance. This 3 layer blown film machine is aimed at making our films more structure ready and planet-friendly. In addition, more modern film types are stronger and easier to print. This means that they are even great for packing various items

There have been vast improvements in Xinfu polyethylene blown film extrusion through the equipment used to make such films as well. This level of accuracy and speed is essential for achieving the demands of consumers; therefore, developing a film quickly while also having it be high grade are crucial factors. These computers ensure that we have the ability to produce films at high quality within the requirements of our customers. Moreover one other incorporating technology like Artificial Intelligence (AI) is utilized to detect the issues/defects that exist in films during production. By utilizing AI in this way, waste is lessened and production becomes all the more efficient

XINFU Polyethylene is totally recognized in its use as a film, and it will be used all around areas like food/beveges, care products etc. Indeed, over the next few years we can expect to see many more creative products made with this film. This being said, the space still needs to evolve customers are demanding more responsible choices when it comes to both environmental and social responsibilities. So we should see continued 5 layer blown film line to develop new materials that not only benefit the environment but are also able to meet customers needs and indeed, desires

Those who have interest in learning about the manufacturing of XINFU polyethylene films, there is a manual available discussing different production techniques. Examples of these methods include blown film extrusion, blown film extruder for sale and co-extrusion. While blown film extrusion creates bubble or tube-like films out of melted plastic, cast film extrusion saves clear transparent flat films. By contrast, co-extrusion brings various types of plastic out into a single film with this unique strength and protective properties which confers multiple advantages

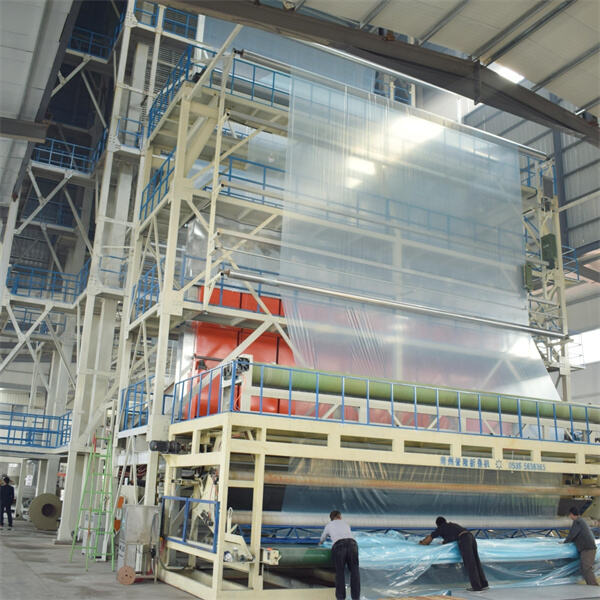

We Polyethylene film extrusion reputable film blowing machines manufacturer over 18 years design and manufacturing experience. We mainly produce geomembrane blowing machine, greenhouse film blowing machine, mulching film blowing machine packaging film blowing machines. We served 200+ customers hope offer high-quality product good service you.

We an Polyethylene film extrusion center engineers have than 20 years RD experience, each your requirements met positive responses create machine meets customer's particular requirements. We'll everything can supply most efficient plastic machines possible each customer.

We place 1-2 engineers Polyethylene film extrusion customer install, operate operator's training. offer after-sales support throughout lifetime machine. We keep touch you during after guarantee service.

company now 2 offices as well research center, Polyethylene film extrusion workshops over 100 employees. are employed in industry more ten years, with wealth experience amazing expertise. production system totally independent comprehensive, which means every component equipment purchase manufactured skilled professionals.