There have been countless advancements in the production of plastic film throughout the ages and innovations that have changed fabricating landscapes for good. A notable variance came in the form of the Mini blown film extruder, a smaller but just as powerful machine which was ideal for small-scale producers and unique applications. The development of these mini extruders has not only democratized film production but also offered pathways in sustainability and adaptability to a burgeoning landscape.

While industrial spaces are being torn apart and production processes become more nimble, mini blown film extruders will have an important role in forming smaller footprinted manufacturing lines. Their small size makes them easy to fit in cramped spaces which is good for businesses who are planning on cutting down business costs by making the factory as efficient as possible. Automation and control systems have evolved as well, allowing these machines to easily interface with Industry 4.0 technologies for improved production quality through the collection and analysis of real time data. Finally, moving forward we should expect even more modular designs that will enable manufacturers to configure their extrusion process lines according specifically to the production needs; improving efficiency and flexibility.

Budget and the resource quasi small scale makers With mini blown film extruders, you will be able to get into the business of producing films with far less money when compared with what would have been needed for large-scale extrusion systems. These equipments do not consume a lot of energy because they are small and the processing is optimised due to which operating costs can be reduced. Moreover, they facilitate shorter production runs and easier changeovers to keep pace with niche markets or special orders - all while keeping downtime and waste of resources at a minimum. Mini extruders provide small business an economic edge by reducing overhead costs and increasing output efficiency.

Sustainability, today even more than in the past, is a must-have for industries globally. The mini blown film extrusion technology is increasingly going green-from the use of bio-based and recycled resins to energy saving designs. Inventions like lower air intake systems and efficient chilling measurers has enabled VM processing to be more significant in extrusion process. New screw designs are increasing melt homogeneity, allowing for better quality films to be made using recycled plastics and aligning with market requirements of the circular economy. Amid a backdrop of increasingly stringent environmental regulations, mini extruders with this green functionality are destined to become essential equipment for manufacturers attempting to adhere systems aligning them with higher global sustainability goals.

Mini blown film extruders are versatile in that they can produce a broad spectrum of film products referenced to different industries. These versatile machines are capable of processing a wide range of resins and additives to address specific performance requirements ranging from agricultural films and food packaging, industrial liners to shopping bags. Their multi-layer co-extrusion capabilities permit them to design intricate film structures, which significantly improve barrier properties with strength and printability. The flexibility to conduct various experiments opens new avenues for manufacturers to tap into novel markets, develop inventive product ranges and respond quickly at the same time when consumers start heading in a different direction trend wise.

Mastering Your Mini Blown Film Extruder Operation Forewarned is forearmed Products Info Videos FAQ Informational Webinars Contact Us Trendy Digital Newspaper A Comprehensive Guide to... - 2 min read

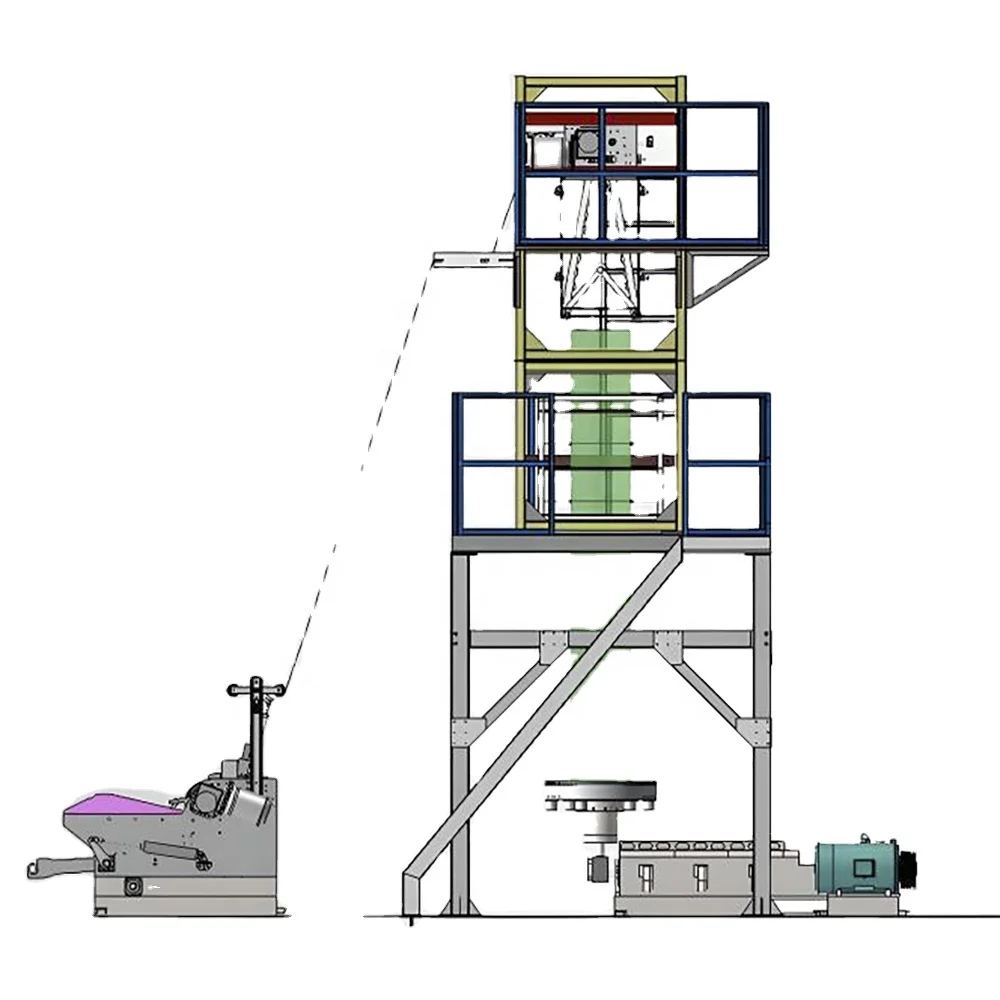

How To Master A Mini Blown Film Extruder Matering the operation of a mini blown film extrude is not easy and requires in depth understanding of some componenets, process parameters & also maintenance routines Operators must understand the barrel and screw design, die head design and cooling system in terms of how each plays a major role in controlling film quality. Variations in temperature, throughput, and blowing ratio affect film thickness, width,and clarity; thus process control is indispensable. Cleaning, lubrication and replacement of worn parts help industrial equipment to exist for a long-time continuation good performance. The operator's skills can be further improved by continuous learning and the technical support provided in cooperation with equipment manufacturers to assist them in optimizing the extrusion process.

In summary, mini blow film extruders are a considerable resource for our current modern-day manufacturing environment-especially for upcoming small-scale enterprises and agile production aspirations. Their capacity to lower costs, adopt environment-friendly practices, serve various applications, and foster the advances in automation highlight them as a strategically important technology for manufacturers of plastic film worldwide. The ability to control these small systems will be critical for manufacturers looking to have a strong position in an ever more efficient, innovative and eco-minded market as technology development advances.

We a mini blown film extruder maker blowing machines film over 18 years manufacturing design expertise. make geomembrane mulching, packaging greenhouse film blowing machines. have served over 200 clients, we look forward providing with highest quality products excellent service.

We send mini blown film extruder engineers workshop customer install, operate training operators. provide after-sales service along lifespan machine. will stay touch you throughout after warranty provide support.

With a RD Center engineers who over mini blown film extruder years RD expertise, be able respond enthusiasm any request design machines meet customers' specific needs. make every effort provide best plastic machines every client.

There now two office buildings, 1 research center, seven workshops over mini blown film extruder employees working us. majority them working field more 10 years experienced talent exceptional skills. production system completely independent complete, you can sure every part equipment purchase manufactured professionals.