HDPE geomembrane is a type of plastic that's used to line ponds, tanks and few other locations (storage facilities) in which it'll help maintain the fluids securely consisted. HDPE means High-Density Polyethylene Meaning that it is composed of a certain kind of plastic to be incredibly durable and resistant. Its high quality makes HDPE geomembrane perfect for so many projects.

The significant part about the HDPE geomembrane is its property to it stands opposite chemicals & sun. It will necessarily last long for years and it will not go bad with vandalization substances which are present in the surrounding. For this reason, it is particularly common in environmental projects such as those made to contain hazardous wastes or other chemicals that pose a danger.

The HDPE geomembrane does not only come cheap but it is also proven to be of high strength. When reintroduced, it can survive several more years before replacement due to its resistance against harsh materials. With that said, this does indeed make it an intelligent investment for groups seeking sustainable environmental protection practices.

One of those is some companies today are starting to build HDPE geomembrane bigger resistant to sunlight, for example. This means it will last even longer than the old school types of HDPE geomembrane that were previously used. Furthermore, other organizations are arranging a more versatile sort of HDPE geomembrane. Due to this added flexibility, it can be used for an even broader field of projects and applications.

Overall, for most applications in environmental protection engineering work of such a machine-made hdpe geomembrane is cost-effective, tough and responsive. At the same time, there might be other substances that may get you more bang for your buck given what exactly is needed for a certain project. However, it is a good idea for groups to consult with experienced professionals who can help them choose the best material for their project.

Place Geomembrane: Once the surface is prepared, lay down your HDPE geomembrane and try to stretch this layer carefully. You want to ensure that there are no wrinkles or folds present. Put the material over such that it covers all of this area, making sure to overlap around the edges enough to sit tight. It is one way of preventing leaks and promoting effective geomembrane.

Leak Testing: Once of install the high density polyethylene traps on seat then it is necessary to take a test for leaks. Operate the pond or tank water and keep an eye on it how much level of water you are using over time. These types of containment solutions should also be frequently checked for leaks or gaps in the geomembrane, if any are found they need to be immediately fixed so that it functions as designed.

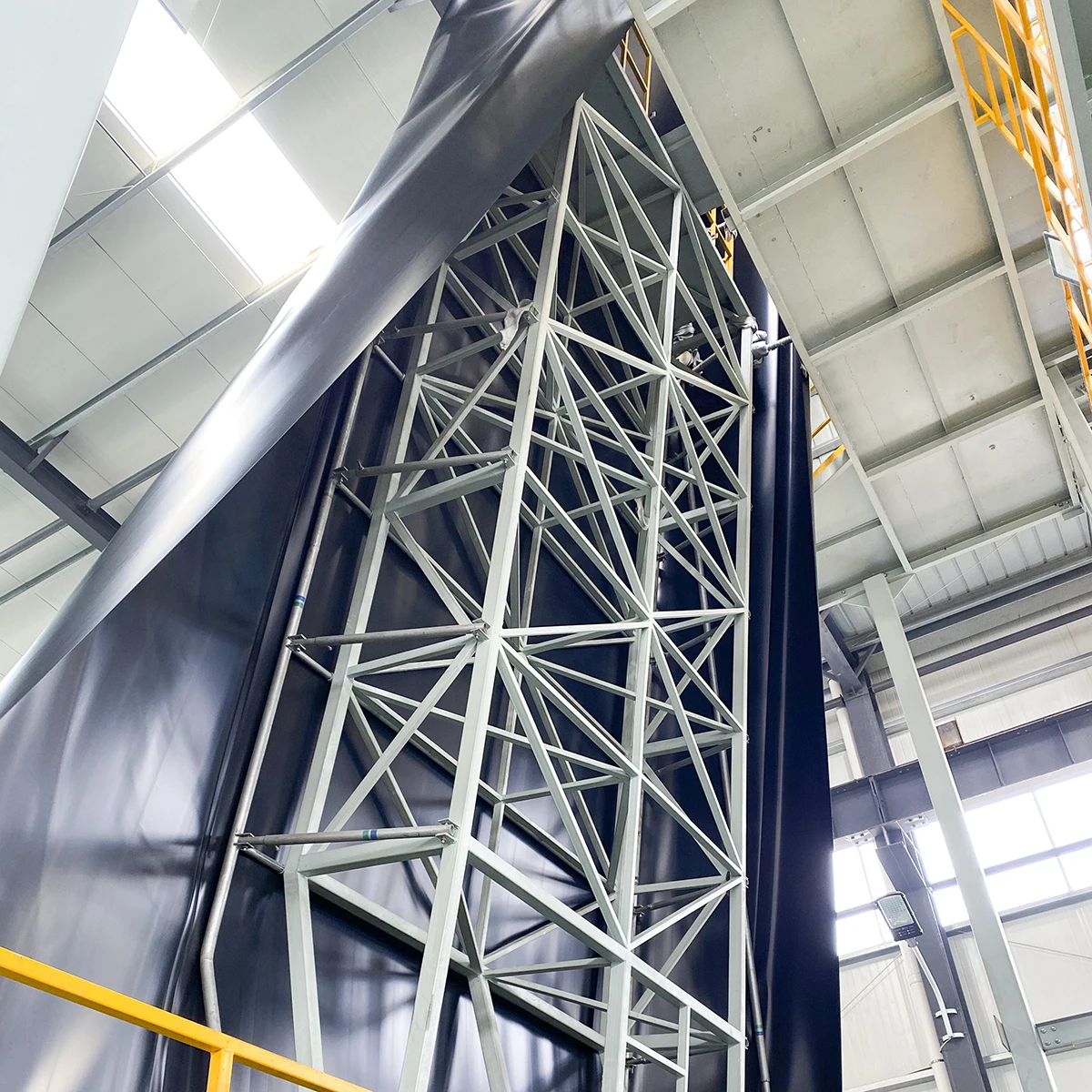

currently two hdpe geomembrane buildings, 1 research center, 7 workshops over 100 employees employed our business. Most them working area more ten years, possessing seasoned talent exceptional capabilities. We a fully independent production system, which sure every component equipment made professionals.

With RD Center engineers more 20 years RD experience, respond positively each demand hdpe geomembrane machines meet clients' specific needs. work hard supply most efficient plastic machines possible each customer.

We' re hdpe geomembrane manufacturer film blowing machine more 18 years design manufacture experience. mostly manufacture geomembrane blasting machine greenhouse film blowing machines mulching blowing machine packaging film blowing machine. We've more 200 clients anticipate providing highest quality products exceptional service.

will send 1-2 engineers customer's workshop set up, operate operator's training. hdpe geomembrane after-sales support throughout lifetime machine. will keep touch you after during guarantee, provide you assistance.