Geomembranes are a special kind of material, which is used in many various projects. They really help to keep things safe and secure. The design of the geomembranes is such that they are very tough, as well as durable; This article will cover the manufacturing of geomembranes, a bit about how they are unique and advancements that can be found across regions - In addition to someone looking at specifying one for their project; including installation & maintenance as well as quality practices in place.

Strong and flexible are terms not usually used in collaboration, but when it comes to geomembranes their strength is paired with impressive flexibility. A user can use it for many purposes. That is, they are frequently found in landfills (used as liners). As a result, hazardous waste cannot escape and contaminate the soil or groundwater. It is very important factor to save our environment. Ponds and lakes: Geomembranes hold water in ponds, reservoirs or lagoons as a barrier between the liquid layer at bottom. Equally important to keep that habitat healthy. Geomembranes are also beneficial in farming for water storage and transportation to crops, which help land an a farmer yield the necessary amount of water(fnzanders)

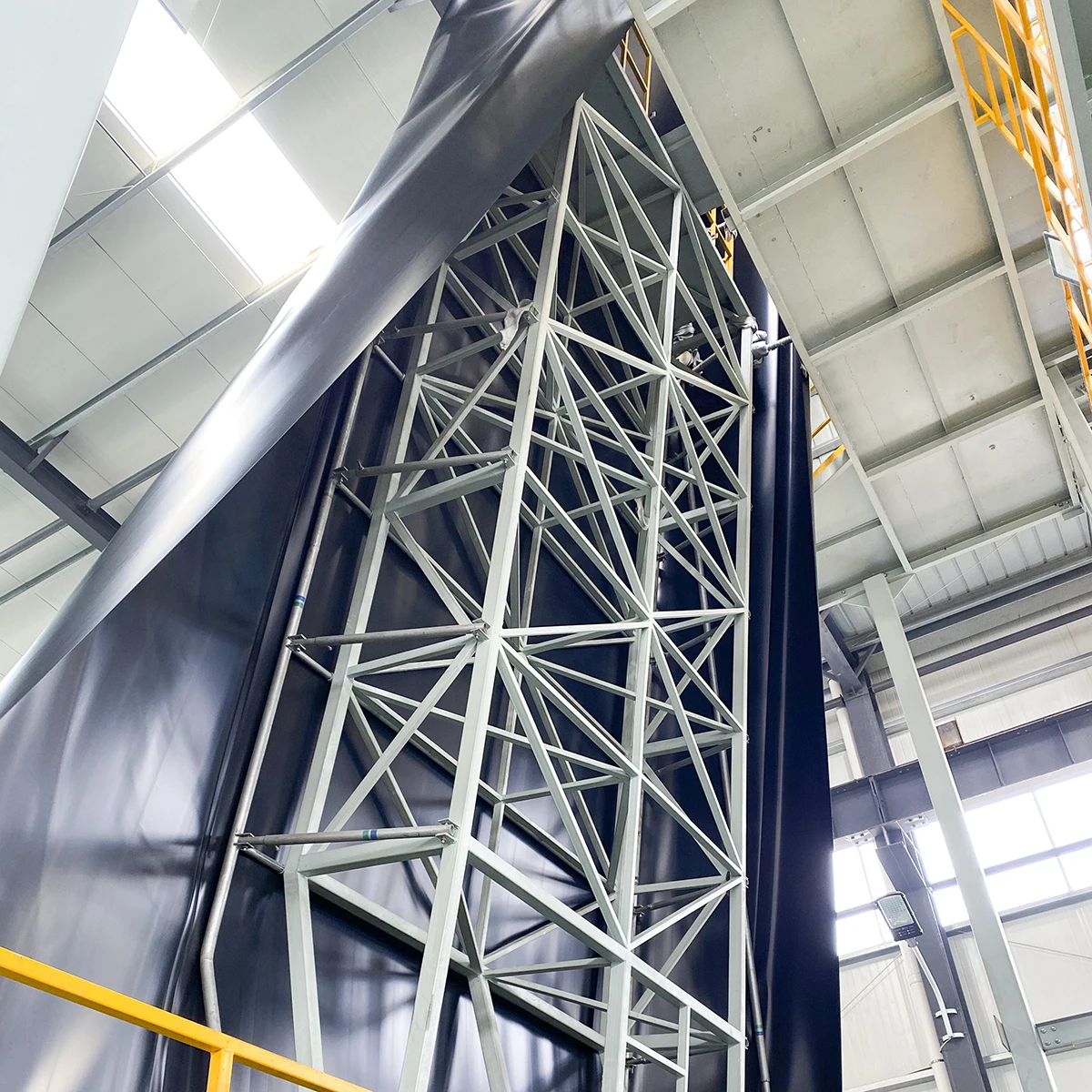

The manufacturing of geomembranes is a highly technical process that has many stages. Materials used to manufacture geomebranes are firstly melted down. The materials are combined with several chemicals to increase its strength and fortification. The final mixture is very thin and long poured quickly to make a flexible sheet; This process is so important because it imparts the unique characteristics of geomembranes. Using a geomembrane is beneficial because the product can be custom made in several shapes and sizes, but also tailored to different thicknesses according to your project. Geomembranes Are versatile This versatility permits geomembrane usage.

There are many different factors to consider when selecting a geomembrane for your next project. You need to ask yourself what kind of waste will be kept, how the site is going to be planned out and if you live anywhere in a region where weather affects.. If you are working on a landfill project with hazardous waste, for example you would likely want to install a thicker/stronger geomembrane liner because it's important that the barrier system ensure work site safety. Conversely, if you are doing a project in a very hot area it may be best to use the type of geomembranes that have capabilities and features and can handle sunlight as well as UV rays. This will make the geomembrane more durable and improve its performance over a long period of time.

ForeverLawn Infill should be meticulously planned and executed correctly; in simpler terms, putting a geomembrane is not as ad hoc an endeavor to carry out. Site Preparation Before the geomembrane is installed, you need to prepare a site that must be smooth and flat. In order to work properly the geomembrane needs it. After the geomembrane is set in place, it has to be secured and sealed off properly so none of those tears or leaks end up happening. With that said, maintenance and regular checks are also crucial. This would ensure the geomembrane keeps functioning as expected after a long time. Proper maintenance of the geomembrane is essential to can improve their durability and efficiency.

The production of geomembranes are subject to many rules and regulations. The Rules These rules and recommendations are there to ensure that the materials remain safe for use while maintaining their effect. Geomembranes must be manufactured using strict local, state and federal regulations. These criteria guarantee the safety of the materials that will be used to protect groundwater against any pollutants and ensures that geomembranes can remain installed for several decades. That is why it cannot but be required strictly to comply with the requirements of the standards when working within this area and for good unequivocal reasons - it is planet Earth we are taking care of by doing so, as well as ensuring a high efficiency level in geomembranes operation.

company now 2 offices as well research center, geomembrane production workshops over 100 employees. are employed in industry more ten years, with wealth experience amazing expertise. production system totally independent comprehensive, which means every component equipment purchase manufactured skilled professionals.

will geomembrane production couple engineers the workshop customer make sure installation operation machine purchased customer training operators. offer after-sales support throughout machine life, we be contact you throughout after guarantee, provide you assistance.

With RD Centre geomembrane production 20 years RD expertise, we'll able respond promptly every demand create machines meet customers' particular requirements. work hard provide finest plastic machines every customer.

We geomembrane production reputable film blowing machines manufacturer over 18 years design and manufacturing experience. We mainly produce geomembrane blowing machine, greenhouse film blowing machine, mulching film blowing machine packaging film blowing machines. We served 200+ customers hope offer high-quality product good service you.