In the world of modern plastic production, compounding extrusion lines are essential. These lines mix raw materials and create custom compounds for specific applications. These extrusion line from XINFU are designed to blend the art and science of material mixing, thermal processing and mechanical design into a robust platform for improving product functionality while unlocking entirely new application possibilities.

So, the future for compounding extrusion lines is tied in with higher automation, be it more clever and efficient working condition of these machines or controlling processes better (optimized) or at all new green solutions. Extrusion lines are starting a new era with smarter production featuring artificial intelligence (AI) and Internet of Things technologies. The integration provides for real-time monitoring, predictive maintenance and optimization of production parameters resulting in increased efficiency and minimized downtime. The adoption of modular designs will further enable them to quickly reconfigure their lines - for an ideal changeover in time so opt for extrusion line machine from XINFU.

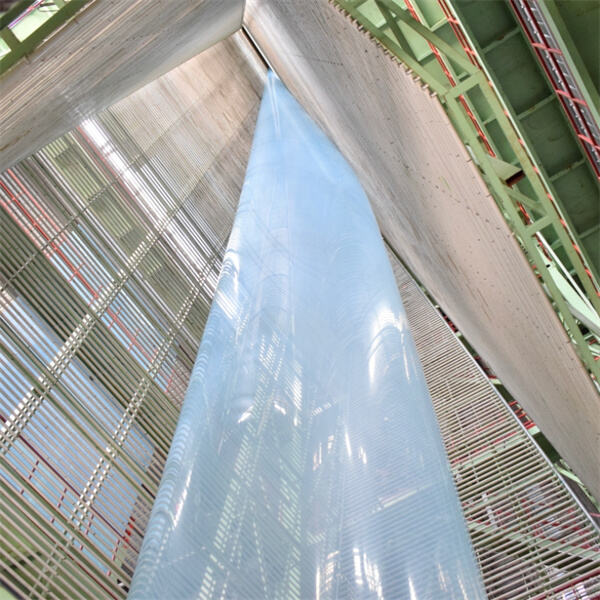

For starters, you need a durable and well-calculated barrel and screw design to both adequately of the heat transfer while maintaining consistent material flow. This extrusion of film from XINFU not only guarantees good mixing, but also facilitates homogenisation of the compound constituents with a view to achieving desired properties. Second, the sophistication of feeding systems is important in handling a variety of ingredients from powders to pellets and liquids with well-distributed blends.

For compounding extrusion technology, they must be more sustainable in the face of increasingly stringent requirements. By implementing eco-friendly solutions are reducing the use of energy, produced waste and also promoting using recycled materials. Although the total CO2 emissions of extrusion are relatively low, energy-efficient drives and optimised cooling systems can reduce them much further. What is more, the 100% recycled content film extrusion also contribute to circular economy efforts.

The compoundability of the extrusion combination lines resides in their flexibility to be adapted according customers' industry. Medical: Extruders must meet requirements as strict cleanliness level and biocompatibility for processing the compounded materials. Functionalities such as in-line blending can be a part of customized extrusion systems for color matching is suitable for packaging, or high-output configurations needed to produce large production volumes and non suitable construction material. This makes film extrusion line possible to develop extrusion lines tailored for you, based on a knowledge of the specific hurdles facing each industry.

We' re compounding extrusion lines manufacturer film blowing machine more 18 years design manufacture experience. mostly manufacture geomembrane blasting machine greenhouse film blowing machines mulching blowing machine packaging film blowing machine. We've more 200 clients anticipate providing highest quality products exceptional service.

a RD Centre engineers more 20 years RD compounding extrusion lines respond positively each request design machines meet clients' particular requirements. do everything can provide best plastic equipment each customer.

company currently 2 office buildings research centre, seven compounding extrusion lines, more 100 employees. majority them been industry than 10 years, a wealth experience exceptional expertise. have comprehensive independent production process ensures each component your equipment designed experts.

will compounding extrusion lines couple engineers the workshop customer make sure installation operation machine purchased customer training operators. offer after-sales support throughout machine life, we be contact you throughout after guarantee, provide you assistance.