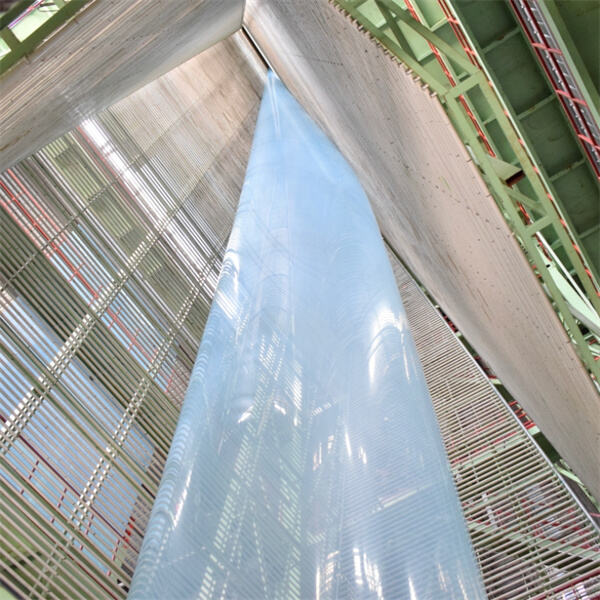

Wind and Rewind Machine for Blown Film

One of the most common packaging materials which is utilized by just about every industry from textiles to food manufacturing would be film and blown film winders are vital in the manufacture. Many sectors throughout the different industries use these machines for its unique features and ensure a safe packaging process.

Out of all these the blown film winder is an exceptional machinery in packaging industry. It is versatile, and therefore can produce a variety of formulated films or tubes ranging from micron to millimeter in thickness making it unrivaled in the packaging industry. It also reduces production waste, making it more cost-effective for businesses. And by using less material than any other machine, it lowers production costs while also pumping out a quality final product. This machine used in packaging lines is very popular among businesses due to the fact that it features a lower cost of ownership, easier operation and requires less maintenance as compared with others.

The point this work note clears up is that the blown film winder operates by assembling all parts of the machine and placing them in a proper working condition as well as inserting film into it while synchronize speed accurately. The XINFU blowing film machine will wrap automatically around a core or bag for easy access during production once the machine is applied.

When you deal with the blown film winder, here are some safety reminders that you should be aware of. Operators must be trained on the specifics of handling this machine. Wear protective gear such as gloves for sharp debris, goggles to protect the eyes, and earplugs or anything that can prevent damage caused by loud noise produced while in operation. Moreover, an empty nook near the XINFU blow film extrusion machine device is also key to preventing anything that might hazard safety.

As technology has evolved, blown film winders have been improved to meet the needs of modern converting and winding operations. To ensure the quality of films produced, several XINFU blow extrusion machine manufacturers have also introduced online measurement and inspection systems. A quick wash function and power/energy-saving, have been additionally personalized available to match uncommon demands of consumers - an attribute which underscores the flexibility as well as trustworthiness from the machine.

blown film winder now 2 offices, research center, 7 workshops, over 100 employees employed business. majority our staff been working industry more10 years highly skilled specialists years knowledge. production process independent complete, ensuring every component equipment you purchase made experts.

We send blown film winder engineers workshop customer install, operate training operators. provide after-sales service along lifespan machine. will stay touch you throughout after warranty provide support.

We an blown film winder center engineers have than 20 years RD experience, each your requirements met positive responses create machine meets customer's particular requirements. We'll everything can supply most efficient plastic machines possible each customer.

blown film winder professional manufacturer film blowing machine 18 years manufacturing design experience. specialize producing geomembrane blowing machine, greenhouse film blowing machine mulching blowing machine packaging film blowing machines. served than 200 clients hope deliver top-quality product great service you.